There are three types of treatment processes to treat wastewater, including physical treatment, chemical treatment, and biological treatment. Wastewater treatment plants (WWTP) usually combine at least two types, depending on the composition of the wastewater. For most contaminants, there is more than one treatment option, and the different methods in question will differ in effectiveness, as well as investment and operation cost involved.

If the WWTP is designed properly and based on an analysis of the wastewater flow and characteristics, the WWTP will effectively reduce contaminant levels to be legally compliant, and thereby reduce river contamination. Effects of wastewater quality and quantity fluctuations are considered highly influential in the selection of the WWTP.

Physical treatment methods

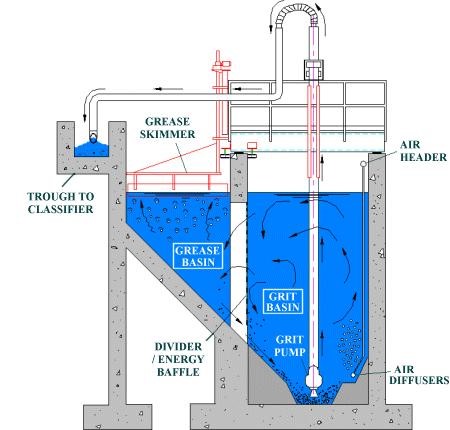

Physical methods are used to remove large objects and non-degradable materials from wastewater. This can prevent pumps and equipment from damage. Processes like screening (Bar screen) sedimentation and skimming (Grit chamber) are used to remove the solids.

One of the main techniques of physical wastewater treatment includes sedimentation, which is a process of suspending the insoluble/heavy particles from the wastewater. Once the insoluble material settles down at the bottom, the pure water can be separated.

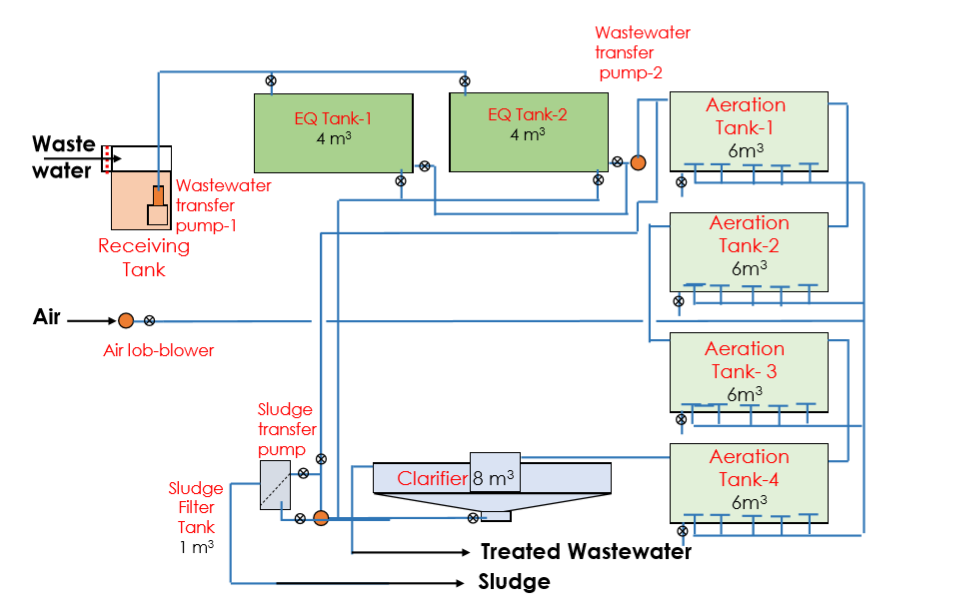

Another effective physical water treatment technique includes aeration. This process consists of circulating air through the water to provide oxygen to it. Filtration, the third method, is used for filtering out all the contaminants. Special types of filters can be used to pass the wastewater and separate the contaminants and insoluble particles present in it. The sand filter is the most commonly used filter. The grease found on the surface of some wastewater can also be removed easily through this method.